Business and Equipment

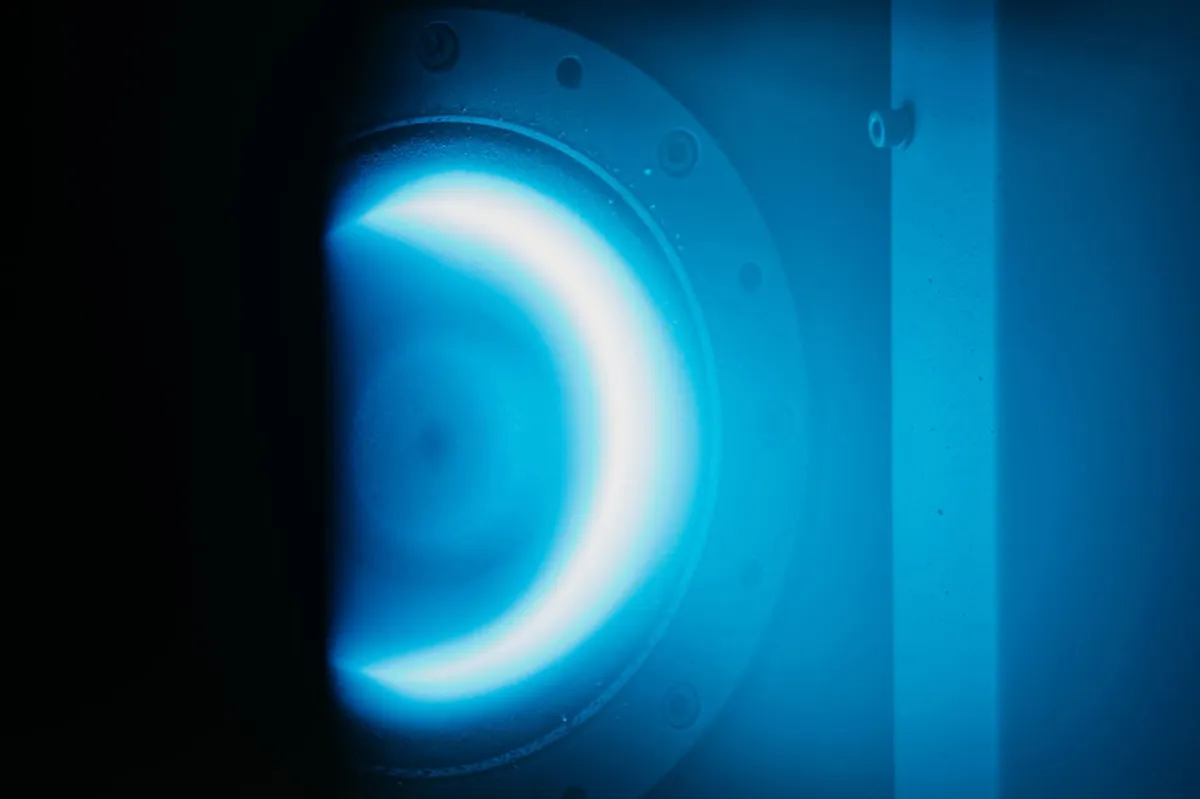

We offer contract processing for thin-film coatings using ion plating and sputtering. By combining reactive gases like nitrogen and acetylene in a vacuum, we can create ceramic thin films. These films provide wear resistance far superior to that of wet plating, thus extending the lifespan of the product. Our coatings are also highly decorative, available in colors such as gold, brown, black, blue, and rainbow. We can process a wide range of materials, including metals, plastics, ceramics, glass, wood, textiles, and paper.

We handle everything from small-scale production, such as prototypes, to large-scale manufacturing. Please feel free to contact us for consultation.

Our wide range of metallic colors can impart a sense of luxury and uniqueness to your products, significantly boosting their market competitiveness.

For example, applying various colors to car emblems or household appliance parts can enhance visual appeal for consumers.

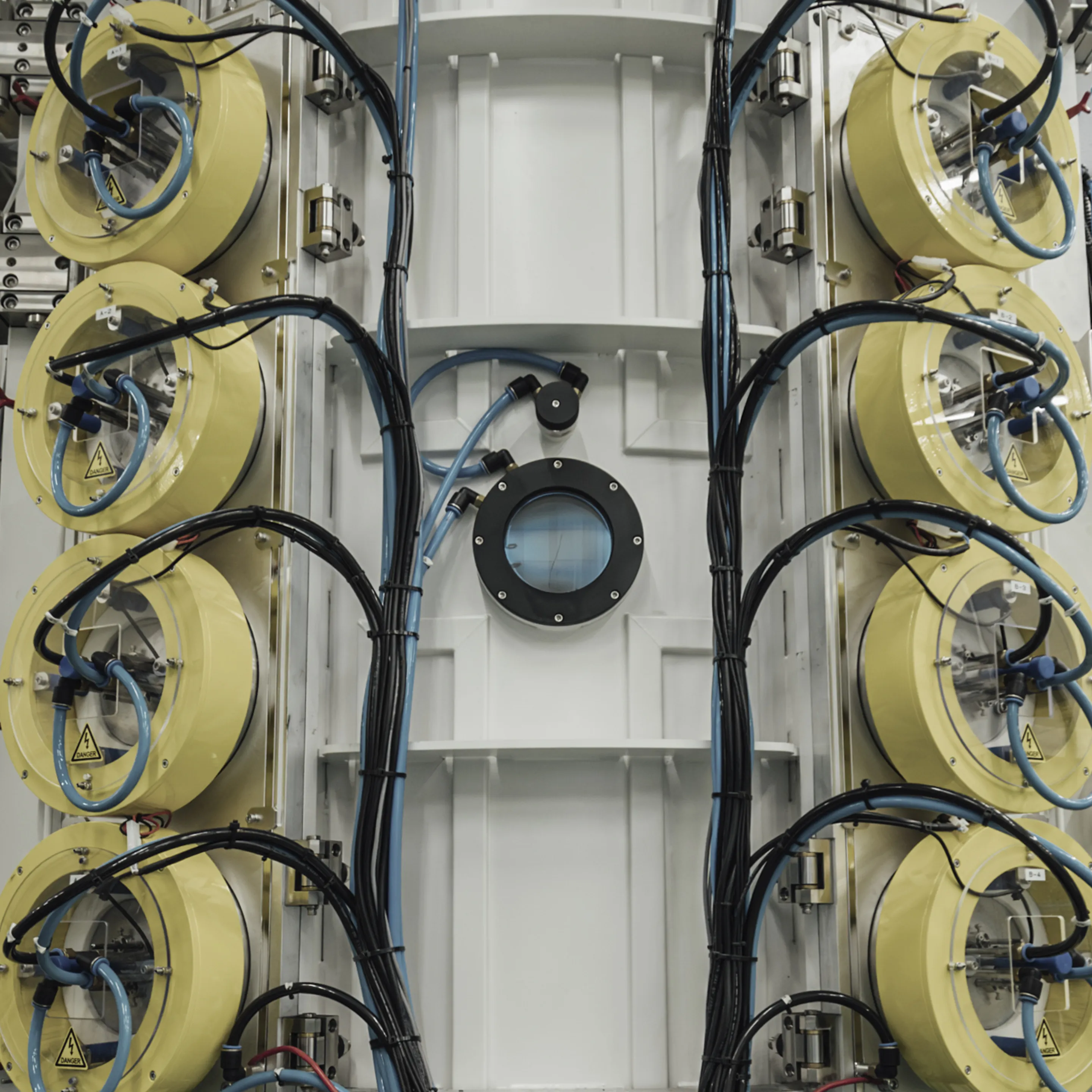

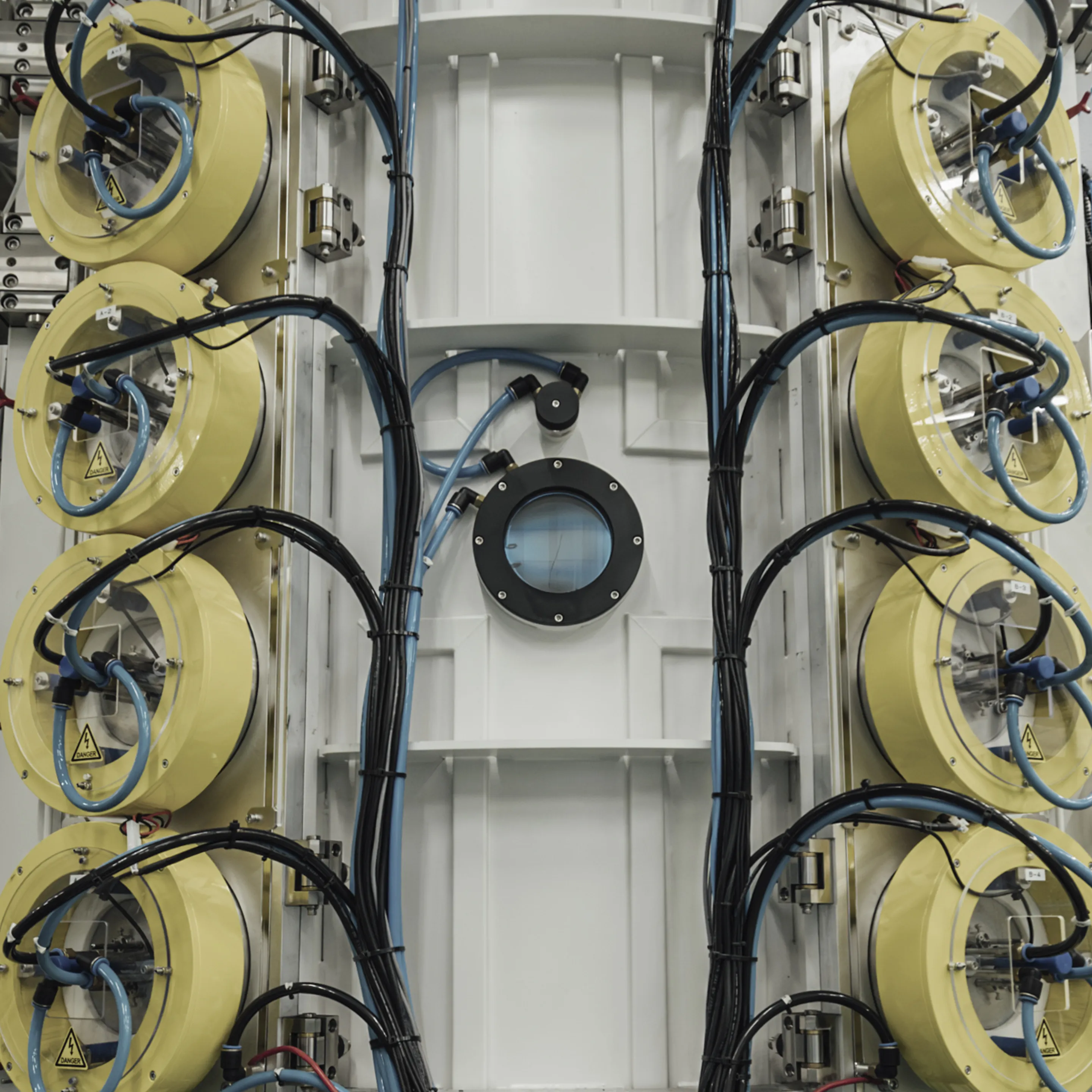

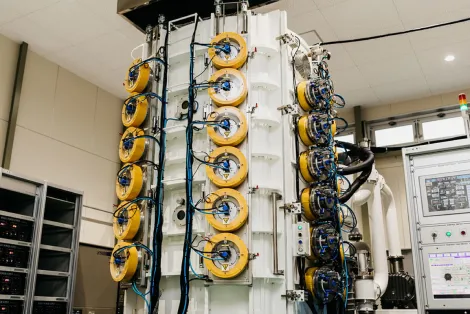

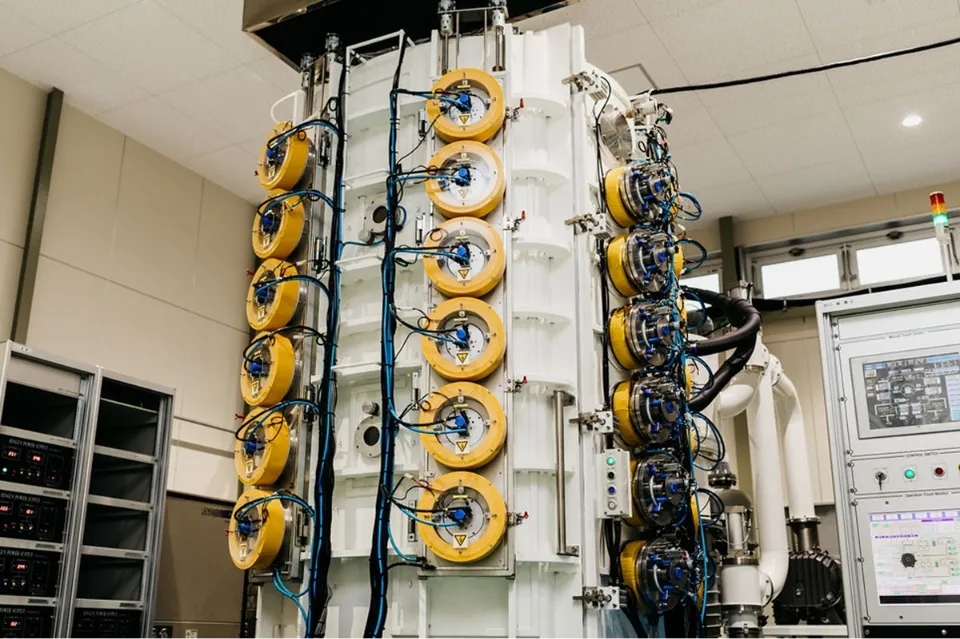

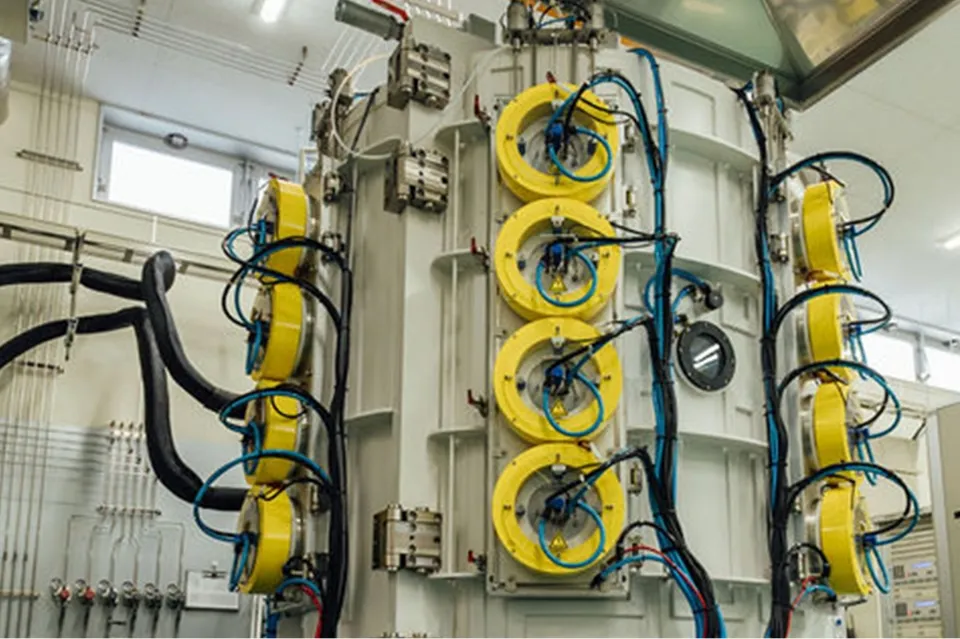

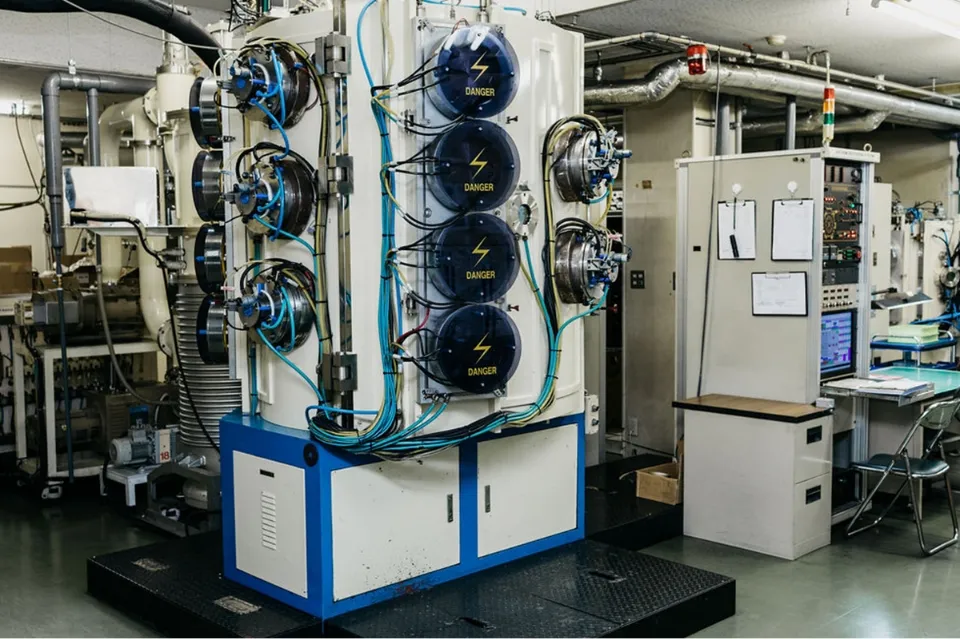

We have state-of-the-art large-scale equipment, allowing us to handle mass production efficiently. By leveraging our extensive production lines, we can reduce production costs and offer high-quality products to our customers at competitive prices.

We implement rigorous inspection standards for each product to ensure quality that meets our customers' expectations. Additionally, we focus on employee education and training to enhance quality awareness and master the latest technologies and inspection methods, continuously improving the overall quality of our manufacturing process.

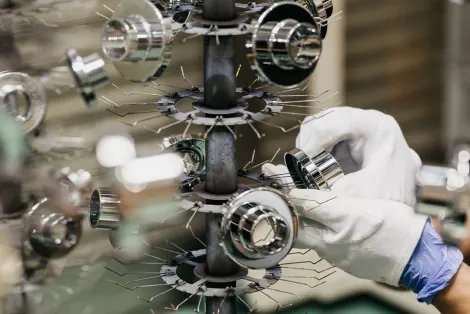

Set the product on a dedicated jig.

Place the product, set on the dedicated jig, into the vacuum chamber.

Close the door of the vacuum chamber.

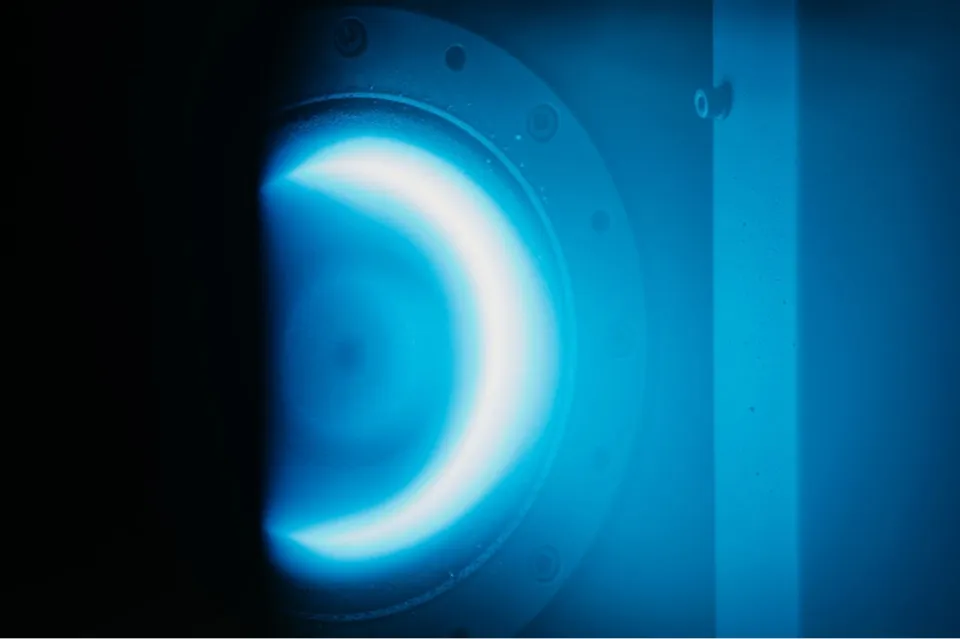

Evacuate the chamber using various vacuum pumps.

Input the processing conditions on the control panel.

Apply a black coating using UBM sputtering.

Conduct a 100% visual inspection inside a non-reflective booth.

Business Hours: Weekdays 8:30 AM - 5:30 PM