What is Ion Plating?

Ion plating is a technology originally developed in the 1950s in the USA, as part of NASA's space and aerospace technologies. It then spread around the world as a method to improve durability in cutting tools and molds.

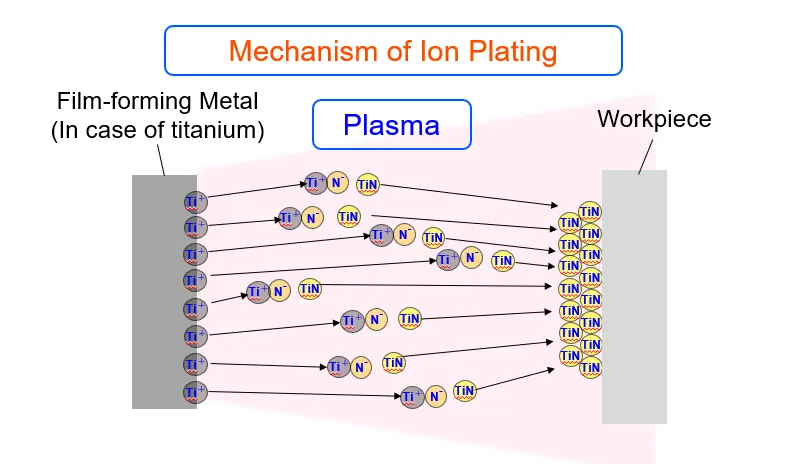

This technology uses heat along with energy from plasma to vaporize metal in a vacuum environment, combine it with a reactive gas to form a ceramic that is then used to bombard (coat) a workpiece. In comparison with traditional wet plating, it is superior in abrasion resistance and adhesiveness.

Our company uses two types of PVD (Physical Vapor Deposition) methods: Arc Ion Plating and UBM Sputtering.

By bonding vaporized metal with reactive gas, a hard, ceramic thin-film can be formed, which is more abrasion resistant than wet plating and effectively improves the longevity of the product.

When discharged, the film-forming metal atoms ionize in plasma with high kinetic energy thereby accelerating and colliding with the workpiece to form a highly adhesive thin film.

Our Ion Plating mainly uses titanium so you don't need to worry about metal allergies. Titanium is biocompatible and rarely causes metal allergies, so it is often used in eye-glass frames, in repairing bones within the body, in screws for dental implants, surgical instruments etc.

Arc Ion Plating is a technology whereby film-forming metal for coating is evaporated in a vacuum environment and ionized by positive charges from an arc discharge, attracting it to a workpiece to which negative charges have been applied, thereby forming a highly adhesive, hard ceramic thin-film. The main metal for film deposition is titanium. Chromium, copper, aluminum etc. are also used. When the film-forming metal is titanium, by injecting a reactive gas such as N2 (nitrogen) or C2H2 (acetylene) to bond with the titanium, a ceramic film coating such as TiN (titanium nitride) or TiCN (titanium carbide-nitride) etc. will form, causing a particular coloring; gold, brown, grey, black etc.

In a vacuum environment, plasma (glow discharge) is generated by injecting an inert gas such as argon that does not react with the film-forming metal, and applying a high voltage between the workpiece and the target (plate-shaped film-forming metal). Positively charged argon ions ionized by the glow discharge then collide at high speed with the target to which negative charges have been applied. As the (sputtered) film-forming metal struck by this collision is attracted to the workpiece to which a negative charge has been applied, a hard ceramic thin-film with excellent adhesiveness will be produced. The main metal for film deposition is titanium. Chromium, copper, aluminum etc. are also used. When the film-forming metal is titanium, by injecting a reactive gas such as N2 (nitrogen) or C2H2 (acetylene) to bond with the titanium, a ceramic film coating such as TiN (titanium nitride) or TiCN (titanium carbide-nitride) etc. will form, causing a particular coloring; gold, brown, grey, black etc.

Business Hours: Weekdays 8:30 AM - 5:30 PM