What is Stainless Steel?

Stainless steel (often referred to as stainless) is a type of alloy steel with high resistance to corrosion. By adding chromium to the main component, iron, a protective layer forms on the surface, making it less likely to rust. Stainless steel is categorized into several types based on its composition and properties. The main types are:

Austenitic Stainless Steel (SUS304, SUS316, SUS316L)

This is the most common type of stainless steel, known for its excellent corrosion resistance and formability. It maintains high strength even at low temperatures and has good weldability. It is used in a wide range of applications, including kitchen utensils.

Ferritic Stainless Steel (SUS430)

While it has lower strength compared to martensitic stainless steel, it excels in corrosion resistance. It is relatively inexpensive and is used in household cooking utensils and construction materials.

Martensitic Stainless Steel (SUS410, SUS420)

Known for its high strength and excellent wear resistance, but with lower corrosion resistance compared to other stainless steels. It is used for knives, valve components, and other applications.

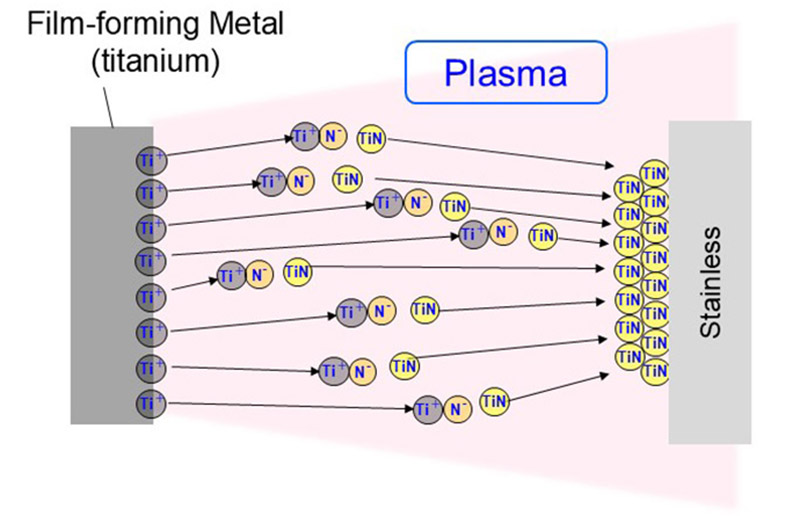

Mechanism of Adhesion (for Gold Plating)

In a vacuum chamber, titanium ions from the plating metal react with nitrogen in the high-energy plasma to form titanium nitride. These particles collide with the product surface at high speeds, depositing in multiple layers. This process creates a coating with strong adhesion.

Effects of Ion Plating on Stainless Steel

Ion plating is a surface treatment technology that enhances both functionality and aesthetics, significantly improving product performance across various industries.

Aesthetic Improvement

By applying metallic colors like gold, brown, black, blue, and rainbow, the decorative quality of the product is enhanced. This improves the design of items such as jewelry and cutlery, adding a sense of luxury.

Enhanced Wear Resistance

Ion plating increases the surface hardness of stainless steel, improving its durability against wear. This extends the lifespan of products used in daily life, construction materials, and machinery components.

Improved Heat Resistance

Unlike other coloring methods, ion plating maintains its performance even at high temperatures, making it suitable for heat-resistant applications such as automotive exhaust components.

Low Friction

The coating smooths the surface, reducing friction. This results in smoother operation of mechanical parts and lower energy consumption.

Reduced Risk of Metal Allergies

Titanium, used in ion plating, is highly biocompatible and is used in medical implants and artificial bones. Therefore, products in contact with the skin, such as medical instruments, tableware, and accessories, can be used safely, significantly reducing the risk of metal allergies.

Examples of Ion Plating on Stainless Steel

Due to its excellent properties, stainless steel is widely used across various industries, especially where durability and aesthetics are crucial.

| Industry | Products | Benefits |

|---|---|---|

| Automotive | Exhaust system parts like mufflers | Wear resistance, heat resistance |

| Hotels & Restaurants | Cutlery, tumblers, tableware, kitchen utensils, cooking tools | Wear resistance, heat resistance, allergy prevention |

| Building Materials | Building facades and interiors, signs, nameplates, handrails | Wear resistance, heat resistance |

| Medical Devices | Dental instruments, tweezers, equipment parts | Wear resistance, allergy prevention |

| Cutlery | Knives, chef’s knives, hairdressing scissors | Wear resistance, allergy prevention |

| Accessories | Necklace chains, earrings, rings | Wear resistance, allergy prevention |

| Temples & Shrines | Ornamentation, door engravings, floral decorations | Wear resistance |

NCC’s Ion Plating on Stainless Steel

At NCC, about 80% of our ion plating work is on stainless steel products. We use four different sizes of vacuum chambers to apply decorations in gold, brown, black, blue, and rainbow.

If you have any questions or requests regarding ion plating on stainless steel or other materials, please feel free to contact us through the inquiry form.