Commitment to Quality

We set stringent inspection standards

for every product.

No relevant processing examples were found.

Please reduce the conditions.

It gives us great happiness to move forward in product development with our clients and share in their excitement.

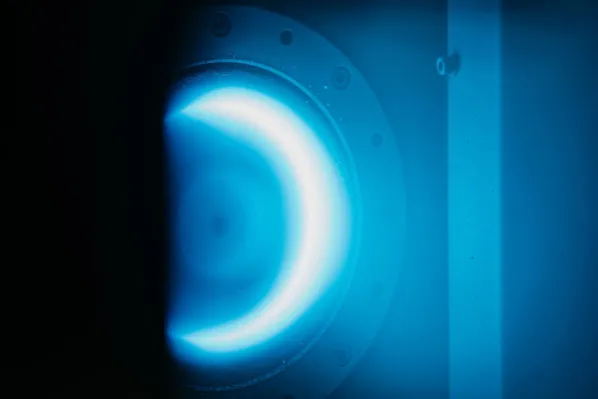

Ion plating is a technology originally developed in the 1950s in the USA, as part of NASA's space and aerospace technologies. It then spread around the world as a method to improve durability in cutting tools and molds.

This technology uses heat along with energy from plasma to vaporize metal in a vacuum environment, combine it with a reactive gas to form a ceramic that is then used to bombard (coat) a workpiece. In comparison with traditional wet plating, it is superior in abrasion resistance and adhesiveness.

Our company uses two types of PVD (Physical Vapor Deposition) methods: Arc Ion Plating and UBM Sputtering.

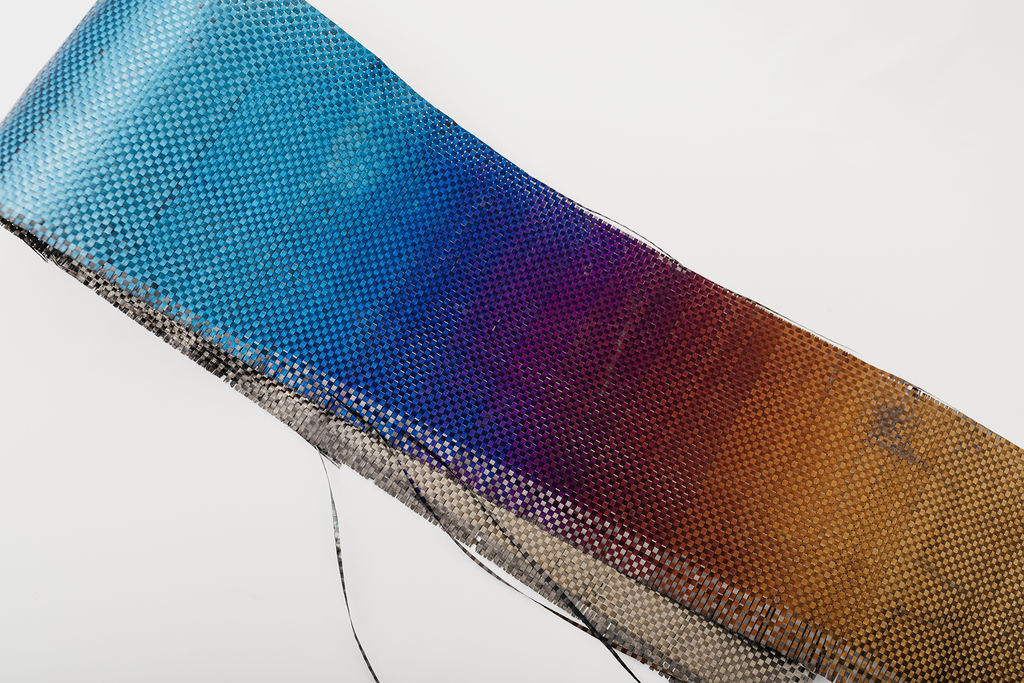

We offer contract processing for thin-film coatings using ion plating and sputtering. By combining reactive gases like nitrogen and acetylene in a vacuum, we can create ceramic thin films. These films provide wear resistance far superior to that of wet plating, thus extending the lifespan of the product. Our coatings are also highly decorative, available in colors such as gold, brown, black, blue, and rainbow. We can process a wide range of materials, including metals, plastics, ceramics, glass, wood, textiles, and paper.

We handle everything from small-scale production, such as prototypes, to large-scale manufacturing. Please feel free to contact us for consultation.

Despite initial financial challenges, the company secured support from Fukui Prefecture's startup assistance program and financial institutions. By inviting former colleagues who shared in the struggles, the business progressed and has now developed to the point where internal engineers handle ion plating processing.

NCC remains committed to the original mission of "contributing to our customers' businesses," and, with the motto of "growing together with our customers," continues to pursue new opportunities alongside customers interested in our technology and business.

Yes, you can.

If you send us a sample item for coating, we will make a prototype in the color you want. There is a basic sample processing fee, however "Pre-ordering samples" etc., will be provided free of charge. Please feel free to inquire.

It takes 1-2 weeks.

Depending on the color, shape, quantity, etc., you will receive your sample about 1 ~ 2 weeks after we receive your item.

You can fill out an inquiry form.

Business Hours: Weekdays 8:30 AM - 5:30 PM